With 44 years of operation in the metal hose business, Hydroflex Solutions has gained a reputation of quality and efficiency. At Hydroflex, we manufacture hoses from 1/4” diameter to 16” diameter in various lengths with various end types. Below you will find an outline of our stocked assemblies as well as a basic breakdown of the variety of hose sizes and types we can offer in our custom manufactured section. All our braided flex hoses are made from raw materials sourced within North America and manufactured at our plant in Nisku, Alberta. Our shop is ABSA certified, and our braided hoses are built to ASME B31.3 specifications. We have CRN certification for British Columbia, Alberta, Saskatchewan, Manitoba and Ontario.

Braided flex hoses can be used in wide array of industries and applications throughout our country. One of the key attributes of flex hoses is their ability to handle certain types of movement. Our flex hoses can accommodate lateral offset motion, angular offset motion, vibration isolation as well as radial movement. Please contact us with any questions or with any information to identify which type of hose will best suit your application.

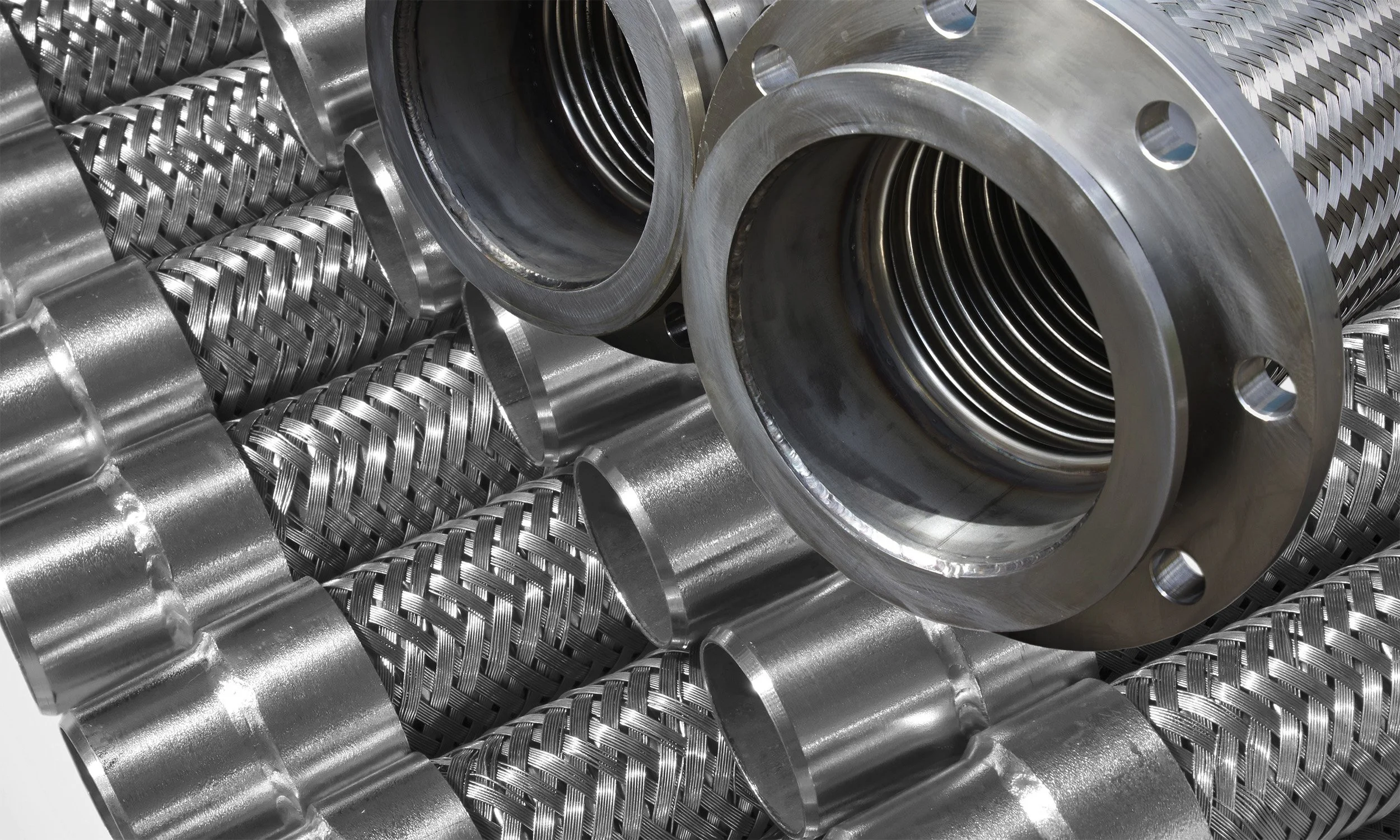

Stainless Steel Braided Flex Hose

PCM-X LINE

Our PCM-X line comes in 1/2” – 2” sizes with varying lengths. All PCM-X hoses have carbon steel (AS/A106) schedule 40 male NPT ends and are good for sweet service; 321SS hose core. Working pressures vary depending on the hose size. All PCM-X assemblies are hydrostatically tested to 1-1/2 times maximum working pressure for 10 minutes. MTR’S and hydrotest report are available upon request.

PCFF LINE

Our PCFF line comes in sizes from 2” – 10” with varying lengths. All PCFF hoses have CL150 A/SA105N raised face flanged ends and are good for sweet or sour service; 316SS hose core. Working pressures vary. All PCFF assemblies are hydrostatically tested to 1-1/2 times maximum working pressure for 10 minutes. MTR’s and hydrotest reports are available upon request.

PCSS LINE

Our PCSS line ranges in sizes from 2” to 4” in 12” overall length. All PCSS assemblies have CL150 F316/L raised face slip-on flanged ends with 316SS hose core. Working pressures vary depending on size. All PCSS assemblies are hydrostatically tested to 1-1/2 times their maximum working pressure for 10 minutes. MTR’s and hydrotest reports are available upon request.

Exhaust Bellows

Hydroflex also offers single-ply bellows for exhaust applications.

Stainless Steel Expansion Joints

One of the most extensive and in-depth products we can offer are stainless steel expansion joints.

Rubber Expansion Joints

Hydroflex Solutions is proud to offer rubber expansion joints manufactured by Proco Products Inc.

Compensators

Compensators are used when there is significant axial movement due to thermal expansion.

Style 240AV Molded Spherical Joints

Hydroflex Solutions stocks the Proco Products style 240AV molded spherical expansion joints in both EPDM (EE) and Nitrile (NP) elastomers.

Universal Expansion Joints

Universal Metal Bellows Expansion Joints are constructed with two metal bellows of equal length separated by a centre pipe.

Custom Manufactured Assemblies

If our stock hose options do not fall within your required specifications or application, Hydroflex can offer custom manufactured hoses to fulfill any application required. Using the same materials as we do our stock assemblies, we are able to manufacture any size hose, at any length with an array of end fittings in both carbon steel and stainless steel.